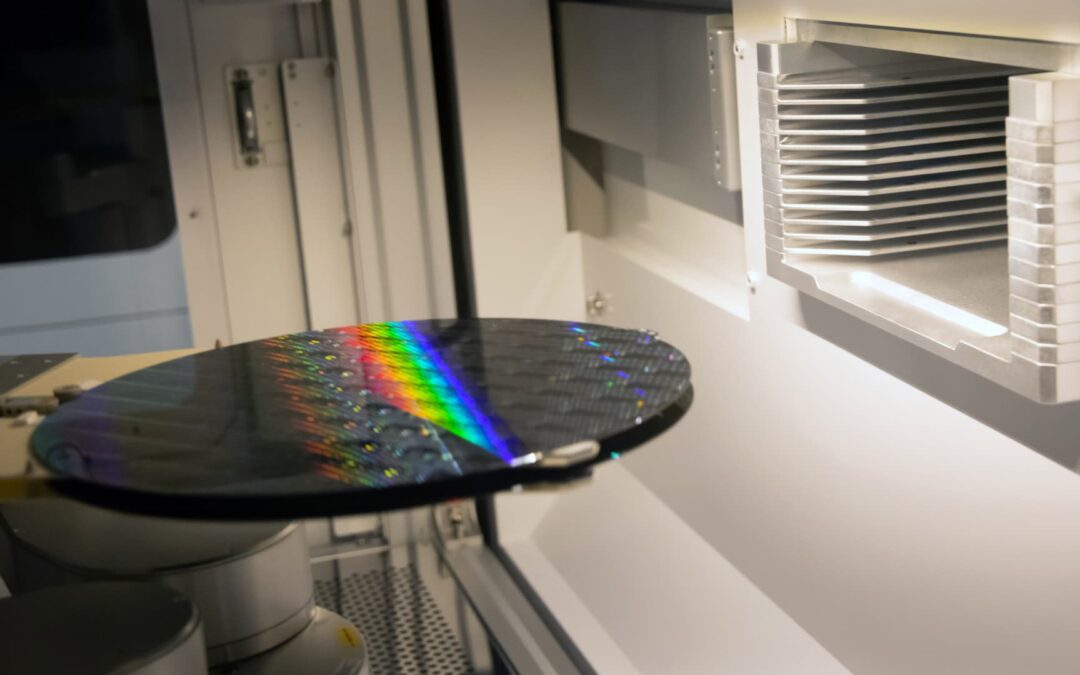

A robotic arm moves 300 mm silicon semiconductor wafers inside a sorting machine in a cleanroom at a Globalfoundries Inc. semiconductor fabrication plant.

Liesa Johannssen | Bloomberg | Getty Images

U.S.-headquartered GlobalFoundries announced Tuesday the opening of its $4 billion expansion fabrication plant in Singapore as the contract chipmaker expects “growth in demand for essential semiconductor chips.”

“I’m confident that over the next decade, this industry will double again,” Thomas Caulfield, president and CEO of GlobalFoundries, told CNBC in an interview ahead of Tuesday’s opening.

Some catalysts include “new and important applications, the whole AI and how that will change society” — which will require chips and create demand, he explained.

“Automotive seems to be staying strong. Cloud for artificial intelligence seems to be strong. Industrial is holding in there. Anything consumer related is still weak,” Caulfield said Monday.

Foundries are companies that are contracted by semiconductor firms to manufacture chips. GlobalFoundries makes semiconductors designed by the likes of Qualcomm, MediaTek and NXP Semiconductors, and serves approximately 200 customers globally.

Its chips are found in smartphones, laptops, automobiles, virtual reality systems, video game consoles, smart speakers, and are also used in AI and 5G.

Singapore supplies 11% of the world’s semiconductors, according to the Singapore Semiconductor Industry Association.

Partnership with Singapore

GlobalFoundries is the world’s third-largest foundry by revenue behind TSMC and Samsung, according to market intelligence provider TrendForce.

The 23,000-square meter fab facility in Singapore will increase the company’s global manufacturing footprint and boost its ability to serve customers across its manufacturing sites in three continents, the press release said.

“As Singapore’s most advanced semiconductor facility to date, the expansion fab will produce an additional 450,000 wafers (300mm) annually, raising GlobalFoundries Singapore’s overall capacity to approximately 1.5 million wafers (300mm) each year,” it added.

GlobalFoundries acquired Singapore’s Chartered Semiconductor Manufacturing and took over its fabs in 2010.

The site’s current manufacturing capacity is 720,000 (300mm) wafers and 692,000 (200mm) wafers a year. Such wafers are the basic material for manufacturing chips.

The new facility will create about 1,000 “high-value” jobs in Singapore, of which 95% will include equipment technicians, process technicians and engineers, the company said. GlobalFoundries currently hires roughly 4,500 employees at the Singapore site.

GlobalFoundries announced in June 2021 the construction of a new fab on its existing Singapore campus, in partnership with the city-state’s Economic Development Board, in order to meet global demand for semiconductor chips at that time.

The following June, the Nasdaq-listed semiconductor manufacturer said its first tool had been moved into the Singapore facility. It also has manufacturing facilities in the U.S. and Germany.

“GlobalFoundries had a long partnership with the Singapore government. The Singapore government has industrial policies about bringing high tech manufacturing, high tech innovation to the region. And it’s why you see so many great companies having manufacturing here,” Caulfield told CNBC’s Sri Jegarajah.

“What happens now is when other nations realize how important semiconductor manufacturing is to their region, for sovereign security, for supply chain, for economic security, they too [will] want to have semiconductor manufacturing, and that they need to adjust their industrial policies to help create that competitive landscape where manufacturing and those regions are economically competitive,” he added.

The expansion will also implement AI tools to improve productivity such as wafer pattern recognition to auto-classify and spot defects in wafers, said GlobalFoundries.

Correction soon?

Smartphone and PC makers are currently grappling with excess inventories of memory chips after stockpiling them during the pandemic-induced boom. As inflation soared, consumers have been cutting back on these goods and prices for memory chips have fallen.

The likes of Taiwanese semiconductor foundry TSMC and South Korea’s Samsung have reported declines in second-quarter profit as weak demand for memory chips continued.

“We’ve seen in the second quarter of this year, inventories at semiconductor companies still climb but at a much muted rate,” said Caulfield. “The good news is we’ve also seen the inventory further down the supply chain, such as system companies, start to go down. And so maybe there is a little bit of a glimmer here that inventory is starting to correct.”

However, global inflation has to be under control first before interest rates can come down and consumer spending can be healthy again, particularly in China, he said.